Columnist

Yuna Hwang Sustainability Management Center

#INTRO

I’ve worked in climate change and sustainability for years, yet whenever I realize my own daily life hasn’t changed all that much, I still feel a twinge of regret. Recently, as I’ve been thinking more seriously about eco-friendly consumption and practice, I wanted to share some honest reflections and changes that have emerged along the way.

1 Earth, Fire, Wind, Water, Heart—What happens when you combine all five powers?

Lately, the theme song from ‘Captain Planet and the Planeteers’—the cartoon I used to watch as a kid—keeps running through my head. Just like the scene where five heroes joined forces to create a champion, it suddenly struck me that Amorepacific is doing something remarkably similar.

Beneath our Yongsan headquarters, there’s a geothermal system harnessing the power of ‘Earth.’ Solar panels across our facilities capture ‘Fire.’ In 2022, we secured ‘Wind’ through a long-term virtual power purchase agreement (VPPA) with the Bukchon-ri wind farm in Jeju. And at our Osan Beauty Park, we collect rainwater to recirculate ‘Water.’

And most importantly, we all carry ‘Heart’—making us modern-day Planeteers in our own way.

These days, my colleagues tease me about showing my age with such dated references, and I take it in stride.

‘Captain Planet and the Planeteers’ from the 1990s

2 Starting in 2025, Amorepacific uses 100% renewable electricity across the entire company.

In Korea, the idea of using only renewable energy might seem unfamiliar. It’s also far from easy. Renewable energy costs more than the electricity typically supplied by KEPCO, and the options for making the switch are somewhat limited or difficult to navigate due to various regulations and methods.

Nevertheless, four years ago, Amorepacific joined the global RE100 initiative and declared its commitment to transition to 100% renewable energy by this year.

Since then, Amorepacific has installed solar panels at every possible location across all our sites. As soon as corporate power trading policies were implemented in 2022, we signed 20-year supply contracts with solar farms in Sangju, Gyeongsangbuk-do, and Dangjin, Chungcheongnam-do. We also secured long-term virtual access to wind-generated power from Jeju, and filled the remaining gap with green premium rates, accounting for the intermittency of renewable energy and lower power consumption at offices.

Last year, we converted all electricity at our production facilities and logistics centers to renewable energy, pushing Amorepacific’s company-wide renewable energy adoption rate past 70%. This year, our goal is to reach 100% across the entire company, including headquarters, R&I facilities, regional offices, and even directly operated retail stores.

Now, incredibly, the electricity we use truly comes from earth, sun, and wind rather than fossil fuels.

Amorepacific Headquarters rooftop solar panels

3 Why go that far?

This is the question I heard most often as the person handling renewable energy initiatives.

It’s not as if customers are demanding, “I’ll only buy products made with renewable energy!” (though that would be wonderful). We’re not being forced to comply with value chain requirements or export regulations either. At most, there’s a growing possibility that carbon footprint disclosures and environmental product information might become mandatory here and there.

As project manager, I would communicate that the renewable energy transition is about “making better products” and “demonstrating leadership in the climate crisis era,” and I’d try to persuade people by pointing out that “renewable energy prices and fossil fuel prices will eventually reach a golden cross.”

But for me personally, the real turning point came from somewhere else entirely. It was when I encountered the LCA (Life Cycle Assessment) results for thousands of products manufactured by Amorepacific. That data contained meaning far beyond mere ‘numbers.’

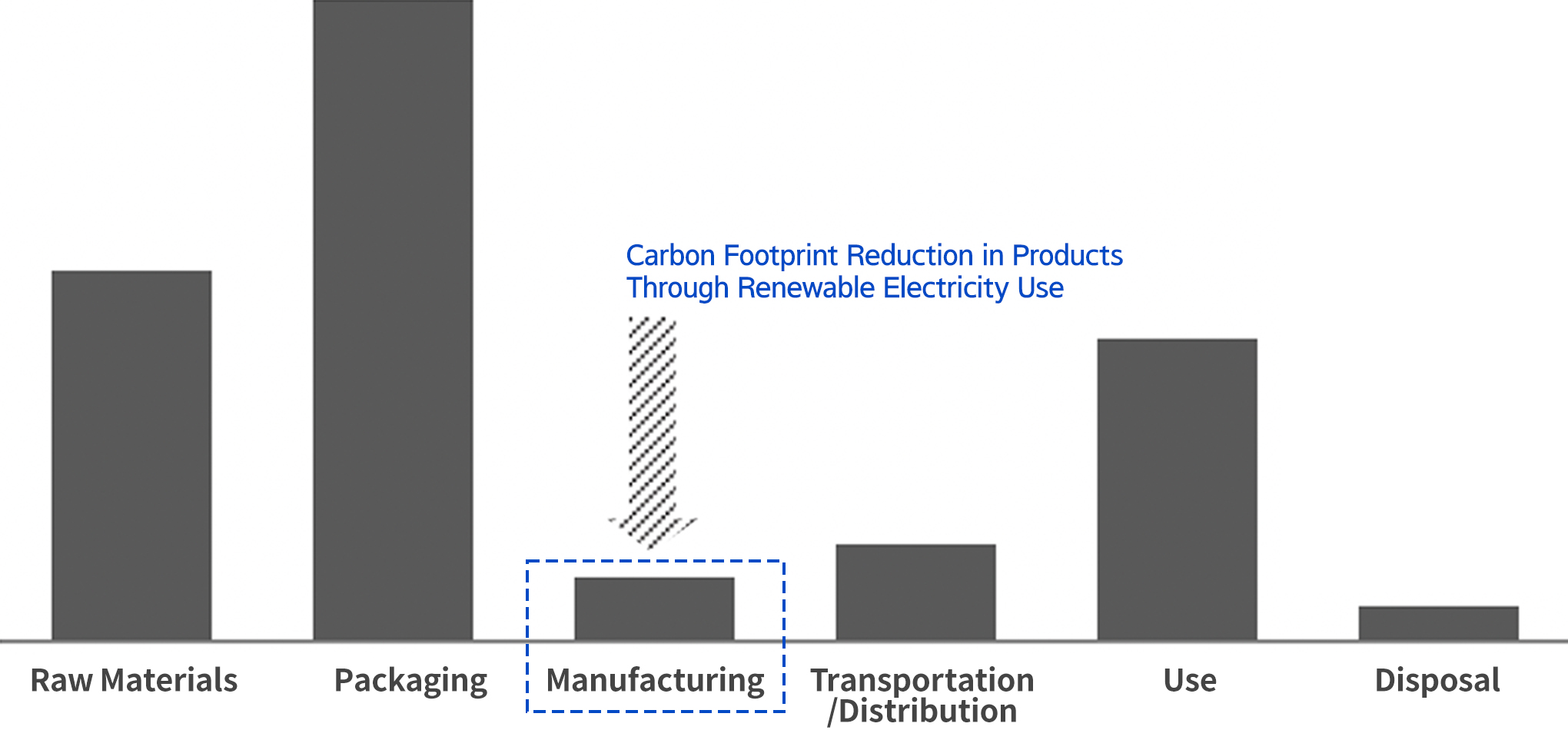

Analysis showed that products manufactured in facilities powered by 100% renewable electricity achieved a reduction of 7-10% or more in their carbon footprint across their full life cycle. When looking only at the manufacturing stage, carbon emissions dropped by approximately 60%.

Carbon Footprint Reduction Case Study - Direct calculation from Amorepacific skincare products

To put it more simply, a product that achieves around a 10% carbon footprint reduction through renewable energy offers an impact comparable to avoiding the production of plastic for two 500ml PET bottles (assuming 11.2g each). If 100,000 such products were substituted in the market, the effect would be to avoid1) greenhouse gas emissions equivalent to the weight of 200,000 PET bottles.

1) Avoided Emissions is a concept that quantifies the contribution of products and services to reducing greenhouse gas emissions compared to existing alternatives. (Source: WBCSD, Guidance on Avoided Emissions v2.0)

4 This isn’t just about building a ‘good company’ image.

This means our activities go beyond simply doing good—they create a structure where consumers can directly choose to contribute to global greenhouse gas reduction. In other words, the act of purchasing products with reduced greenhouse gas emissions can influence every stage of product manufacturing.

As improvements accumulate across climate- and environmentally-positive products, the ripple effects—including avoided emissions—grow exponentially, serving as a catalyst for lowering carbon intensity across entire industries.

In the age of climate change, I believed the first thing we could do was transform the ‘manufacturing’ domain where we have direct control. But from a life cycle perspective, this change wasn’t just ‘our’ responsibility—it was a challenge we all needed to tackle ‘together.’ Furthermore, the LCA data clearly showed us the direction for that change: where to start and what the next steps should be.

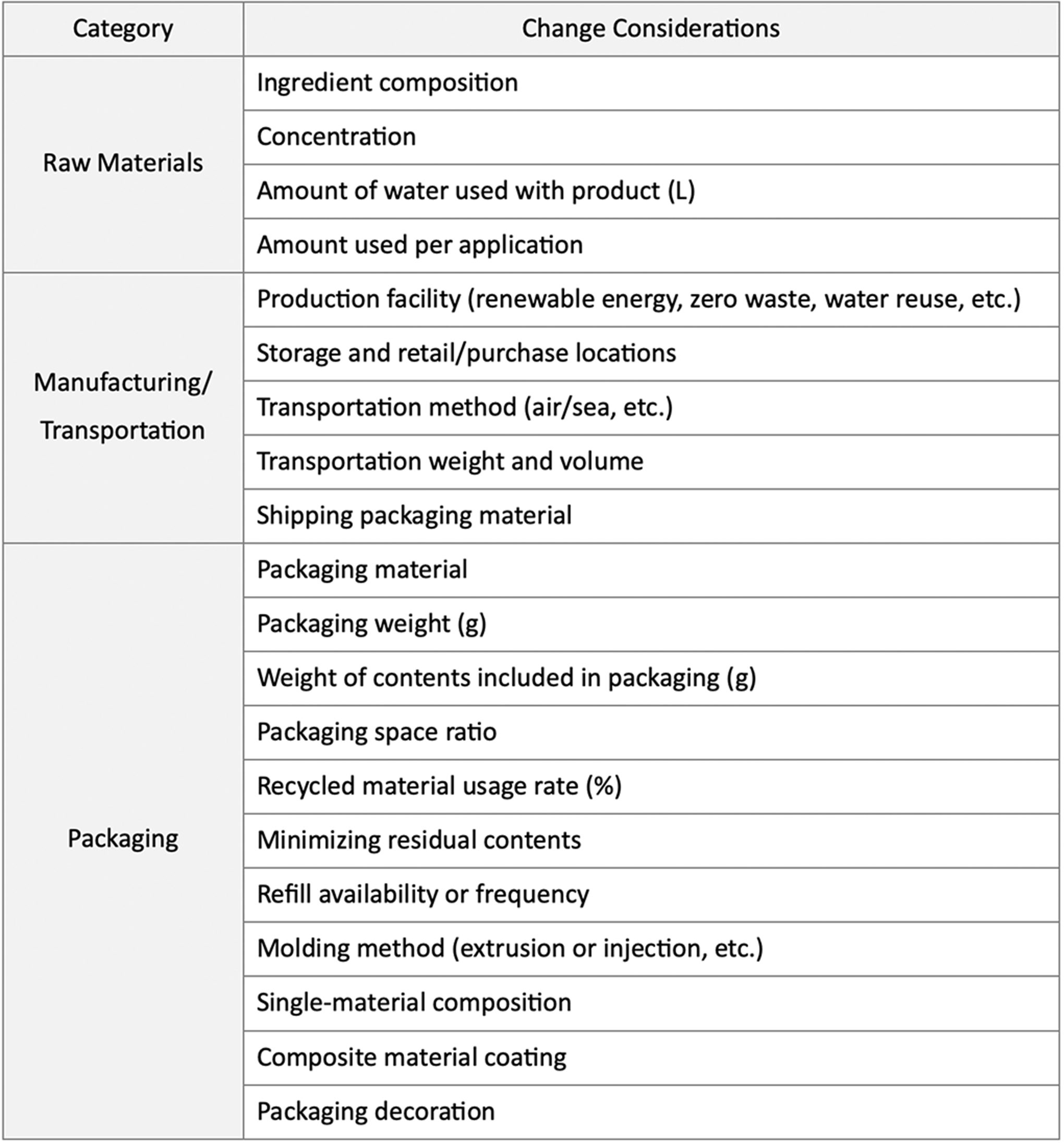

As a result, new opportunities for differentiation began to emerge for marketers, researchers, and packaging departments developing products. Here’s a simple summary of the key factors that can serve as kickstarters:

Factors for Minimizing Environmental Impact Across the Life Cycle

In truth, these elements have been with us for decades under the name of eco-design. But the impact, as quantified, exceeds what we had imagined. And LCA-based decision-making isn’t just about making eco-friendly products—it’s a smarter strategy for enhancing brand competitiveness and market trust.

Now is the time when everyone, at every stage, needs a framework for measuring and improving together.

Today’s small changes, starting with measurement, will become tomorrow’s standards, and those standards will ultimately shift the direction of entire industries.

#OUTRO

This year, I worked with colleagues who wrote ESG-related columns, thinking about how we could communicate more easily and engagingly. Rather than simply listing information, we wanted to share the meaning behind why we need to drive these changes.

I hope this offered a fresh perspective, even in a small way. If the opportunity arises, I look forward to connecting again with deeper insights and more stories to share. Thank you.

|

Yuna Hwang |

|

|

Amorepacific

|

|

-

Like

0 -

Recommend

0 -

Thumbs up

0 -

Supporting

0 -

Want follow-up article

0